AMMUNITION HANDLOADING

SAFETY. PRESSURE.

As time passes, just about everything improves with technology, ingenuity, and demand, and handloading is no exception. And, while I'm not always complementary toward the legal profession, I believe that the liability concerns of component manufacturers have contributed to handloading safety, helping to make it safer than ever. Additionally, a huge step forward, in terms of safety, is due to an industry wide recognition of the

need for specific handloading data that takes component characteristics and firearms Into account.

When you boil the subject of handloading safety down to the ONE thing, it is all about

PRESSURE. Most of the catastrophic failures that were pictured in post number one, above, were due to OVER PRESSURE conditions.

During the net, we intend to cover these topics, all of which are pressure related:

SAAMI

loading data manuals

the 4 components of ammunition, and their effects on pressure

chronographs

visual inspections and what to look for

non lead bullets

life span of brass

barrel twist

bullet seating depth

SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute, https://saami.org/)

Among the many things which SAAMI does, it includes publishing pressure standards, which are maximums for different cartridges. Here is what they say:

About SAAMI

The Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) is an association of the nation’s leading manufacturers of firearms, ammunition and components. SAAMI was founded in 1926 at the request of the federal government and tasked with:

Creating and publishing industry standards for safety, interchangeability, reliability and quality

Coordinating technical data

Promoting safe and responsible firearms use

SAAMI Strategic Goals

1). Create and maintain technically-correct standards for terminology, performance, interchangeability, and safety regarding firearms and ammunition.

2). Continually improve and share our expertise with policy makers and strategic partners related to technical performance and safety regarding firearms and ammunition manufacturers’ issues.

3). Continually improve the forum by which members consider and analyze appropriate standards and policies regarding firearms and ammunition.

4). Monitor, anticipate, and address new technology, opportunities, challenges, and emerging trends impacting the mission of SAAMI.

5). Increase SAAMI’s public visibility as “the experts” in our fields.

Our Mission

To create and promulgate technical, performance and safety standards for firearms, ammunition, and components; and to be the preeminent global resource for the safe and responsible transportation, storage, and use of these products.

LOADING DATA MANUALS

Loading data manuals use the SAAMI standards in the preparation of these manuals. They also conduct extensive testing, with very expensive equipment, in dedicated laboratories, to insure that their load recommendations are safe. When they give loading data, it is the result of this testing, which is why it is wise to follow their recommendations.

There are several companies that publish this information, and with no exceptions, (of which I am aware), they all are excellent. Three things are important for the handloader:

- have more than one manual or data source

- have loading data that matches, as closely as possible, your particular components and firearm,

The most important advice in all this is to begin every new cartridge handload at the minimum, working you way up incrementally, and do NOT EXCEED powder recommendations. While this is THE most important consideration, don't under estimate the importance of component selections, e.g. primer, bullet and brass.

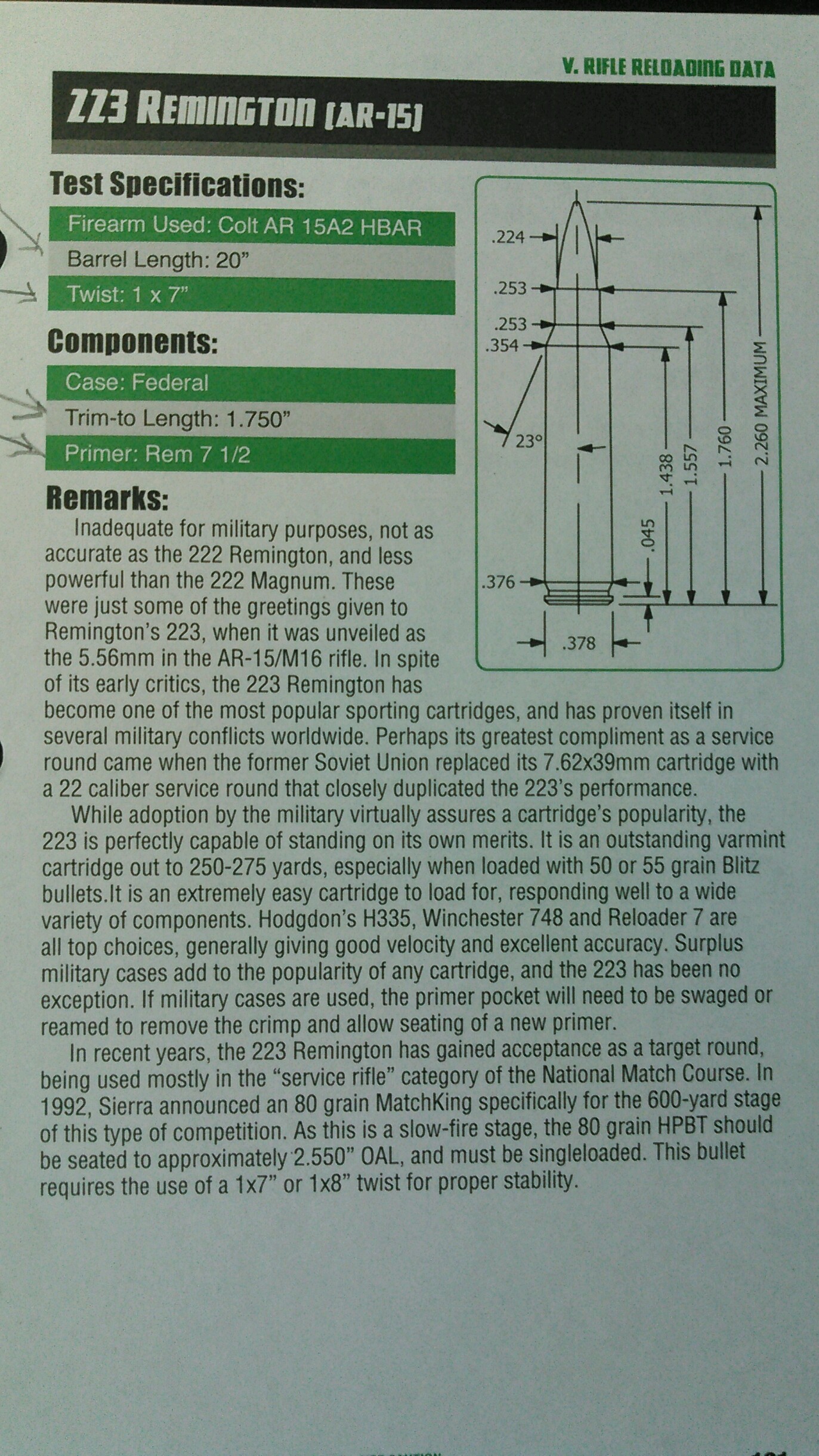

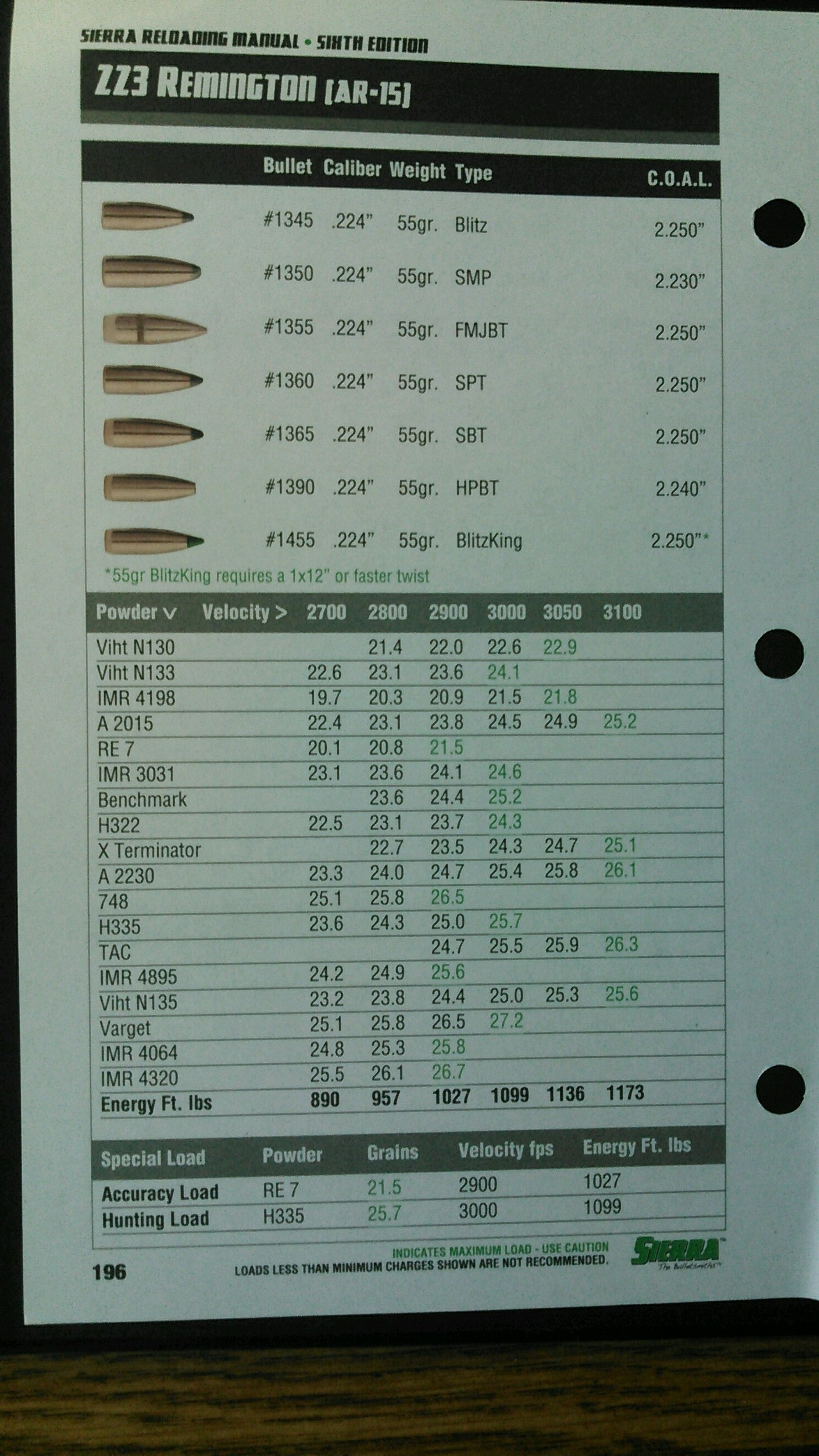

Every handloader will settle on a favorite handloading manual. Mine is Sierra. More on the net, but here are two pages from their manual for the .223 Rem:

- Sierra Loading Data .223-2.jpg (808.69 KiB) Viewed 905 times

- Sierra Loading Data .223-1.jpg (774.53 KiB) Viewed 905 times

CHRONOGRAPHS

While it may seem like a luxury, a chronograph is a very important safety factor in the process of making your own ammunition. Technology has made some significant changes in the chronograph market, the most notable of which is cost. For about a $100.00 you can get a high quality chronograph that will give you the important feedback on your handloads you will need. More on the net.

Here is an example of a chronograph set-up:

- Shooting - chrono, bench, target cam6 (Large).jpg (182.82 KiB) Viewed 905 times

- Shooting - chrono, bench, target cam4 (Large).jpg (72.86 KiB) Viewed 905 times

NON LEAD BULLETS

Yes, different bullets will create differences in pressure. One of the more recent developments in handloading is the need to recognize the loading requirement for copper bullets,(which can differ significantly from lead.) This picture gives a visual reference on how these two metals differ. More on the net.

- Lead vs Copper.jpg (888.26 KiB) Viewed 905 times

COMPONENT VARIABLES

Powder, brass, primer, bullet, and Bullet seating depth. More on the net

BULLET SEATING DEPTH

For those who are not familiar with the reason for varying bullet seating depth, there is just one word that explains it - ACCURACY!! AND, it works. The Barnes Bullet company routinely recommends varying this depth, and says this (

http://www.barnesbullets.com/load-data/):

When loading a Barnes TSX, Tipped TSX or LRX bullet, your rifle may prefer a bullet jump of anywhere between (a minimum of) .050” up to .250” or more. This distance off the lands (rifling), aka "jump" may be limited to the rifles throat length, magazine length and bullet length.

When selecting the cartridge overall length (COAL) we recommend starting with a minimum “jump” of .050” off of the lands. You can test different seating depths and find a “sweet spot” that your particular firearm prefers. We suggest working in at least .025” increments as follows seating the bullet deeper to allow a further jump.

But, BE CAREFUL. In the quest for the greatest accuracy, many handloaders get very close to the lands, and some even use dead length seating (having the bullet actually touch the lands.) In the context of this discussion, it bears emphasis that land engagement WILL increase pressure, which if acknowledged, is easily solved by reducing the powder charge.

Here is an example of over pressure, due to bullet seating depth. Note the primers are flattened and cratered. The solution was simply increasing seating depth.

- 30-06-2.jpg (1019.65 KiB) Viewed 905 times

OVER PRESSURE SIGNS

As mentioned earlier, safety isn't only what you do when creating your ammunition, but it is also your observations of certain signs once you have fired it. In addition to the chronograph (which should be your first indicator of pressure), your fired brass can also show signs of over pressure, but not always. Some of the signs to look for are primer condition (as above,) pressure rings, blown primers, primer pocket enlargement, case head expansion, and ejector imprints on the case head. Also, difficult case extraction can be another indicator. The best explanation I have seen on pressure evaluation is in Glen Zediker's book, "Top Grade Ammo", from page 254-268, and appropriately entitled, "PRESSURE."

One important note here. The absence of visual signs of over pressure does not mean that everything is just fine. Because manufacturers build a certain amount of safety margins into their products, which may temporarily prevent any observable signs of over pressure, you may find that a constant diet of the high pressure stuff, eventually results in a spectacular failure. That is why there are limits. Observe them!!!!!!!

Here are some pictures that

MAY indicate high pressure:

ejector imprint

- Over Pressure - ejector imprint.jpg (44.77 KiB) Viewed 905 times

blown primer

- Over Pressure - blown primer.jpg (16.67 KiB) Viewed 905 times

pressure ring

- Over Pressure - pressure ring.jpg (127.8 KiB) Viewed 905 times

BE SAFE. BE SMART.