These photos will be discussed by Kevin during the net. Note: they are numbered for easy reference.

What follows are Kevin's comments:

The purpose of this Net is to help you understand how various adhesives and sealants can

Improve the reliability, safety and longevity of not only a vehicles mechanical assemblies, but also Ham radio

equipment, outdoor and camping gear.

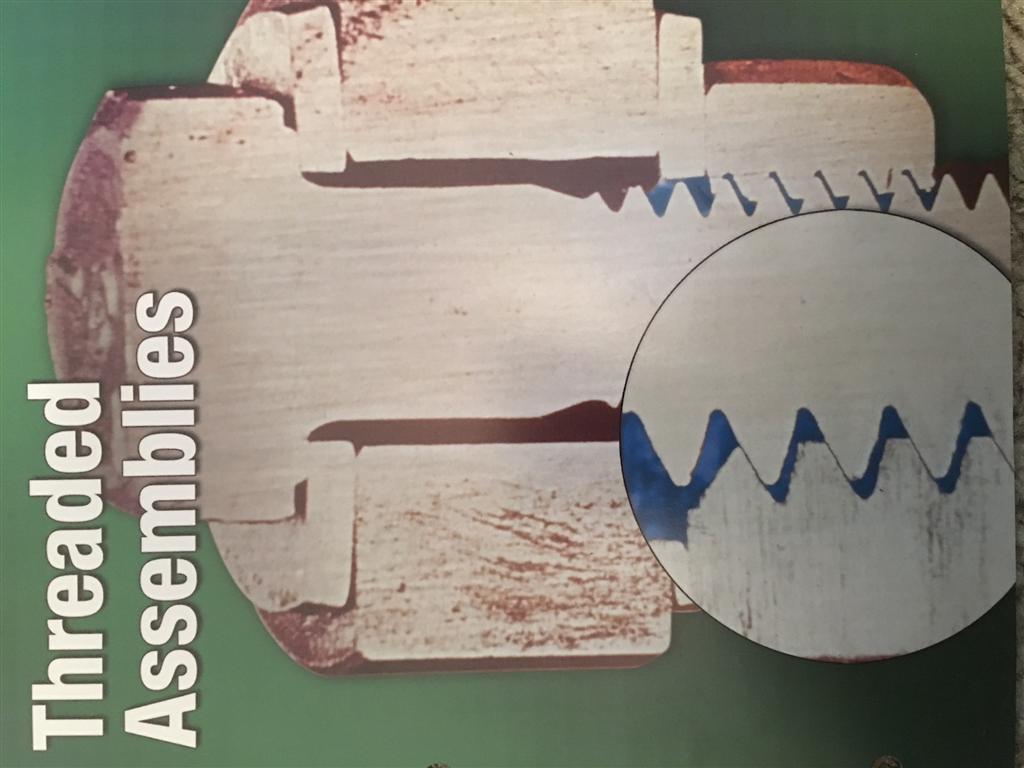

Photo # 1

At the end of this Net, you will be able to:

1. Describe the different adhesive chemistries and their benefits/challenges

2. Understand how to select the correct version to best solve your problem

3. Describe the failures most likely to occur on the trail that can be prevented or repaired with adhesives

4.Prepare your own adhesive kit that will augment the other "Tools" you carry.

5. "STOP USING SPLIT RING LOCK WASHERS".

Topics include:

Thread lockers vs traditional locking devices

Anti Seize and lubricants

Cyanoacrylates(Super Glues)

Liquid Gaskets and Sealants

Epoxies- liquids and putties

Solvent based adhesives

Two Step Acrylics

- Image1 (Large).JPG (60.09 KiB) Viewed 834 times

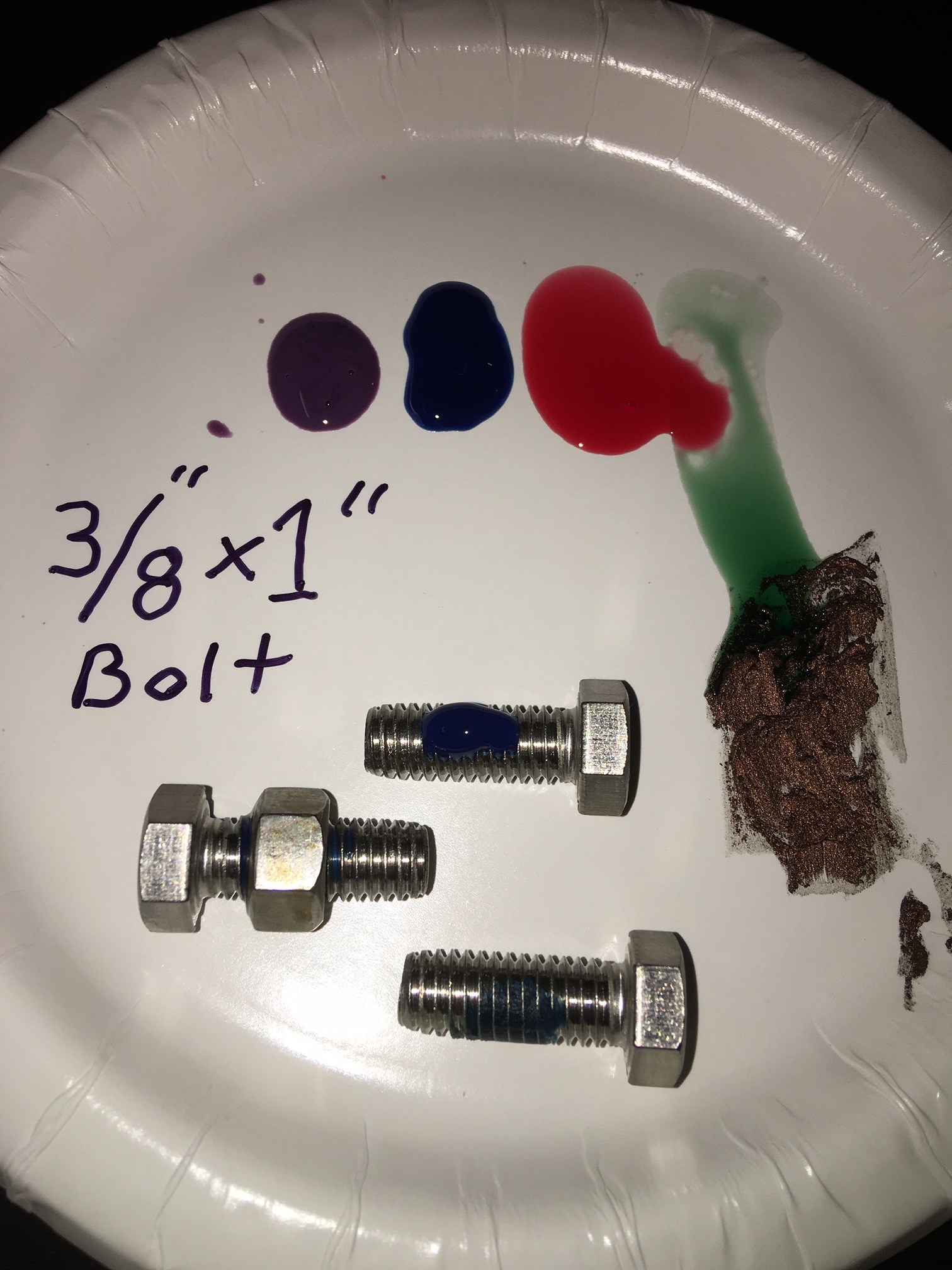

Photo # 2

1. Anaerobic chemistry cures with lack of air and the presence of metal ions. They never dry.

2. Can stress crack some plastics. Nylon insert lock nuts are fine.

3. Increase friction by filling the air space with a hard plastic.

4. Lubricate going on, prevent rust and galvanic corrosion.

5. Allow for disassembly with no damage to assembly if proper strength selected.

- Image2 (Large).JPG (68.19 KiB) Viewed 834 times

Photo # 3

Typical fastener with Blue, removable thread locker.

1. A standard threaded assembly has about 15% metal to metal contact between the threads. The rest is air space. By filling the air space with a hard plastic, you greatly increase the friction with the added benefit of sealing the threads

2. It takes as little as 100 vibration or shock load cycles to start fastener failure.

3. Fastener failure means loss of clamp load. It is the loss of clamp load that causes many squeaks and rattles that lead to wear in mechanisms.

4. It is the air space between most assemblies due to imperfect fit that initiates wear or failure.

5. Fill up the air space, reduce failure.

6. Always use hardened flat washers and nuts when using hardened bolts.

- Image3 (Large).JPG (71.13 KiB) Viewed 833 times

Photo # 4

Thread locker selection:

1. Purple is low strength for fasteners under 1/4" or when some adjustability is desired.

2. Blue is medium strength and is your first choice. Both purple and blue are removable with the same hand tool you put it on with. Useful for most fasteners above the drive train. Excellent for securing vehicle accessories including Ham radios equipment.

3. Red is high strength. You need 450* F for 5 minutes to remove it. Used for high torque or shock applications. Motor or shock mounts. Also may be used for tamper resistant applications.

4. Green( sometimes blue) is a wicking thread locker for post assembly applications. Line up your assembly and tighten the fasteners. Then add a drop of wicking thread locker to lock and seal.

5. 2 free falling drops on a 3/8" bolt are all you need.

Anti Seize

1. Lubricates going on

2. Fills the air space to prevent corrosion

3. Aids in disassembly

4. Does nothing to lock fasteners together.

- Image4 (Large).JPG (739.44 KiB) Viewed 831 times

Image #5

Blind hole applications.

Threaded fasteners in engine block, differential, etc

You must put the thread locker in the hole.

1. The H ole on right is a through hole. Apply thread locker to fastener. T/L is distributed during assembly.

2. The hole in middle is a blind hole. It does not have an exit hole. T/L was applied to screw and inserted. The air in the hole was compressed and most of the blue T/L was forced out with the air. Notice the bubbles at the top.

3. Proper assemble of a blind hole fastener requires putting the blue or red T/L in the hole before assembly.

- Image5 (Large).JPG (54.23 KiB) Viewed 833 times

- Add on (Large).JPG (43.52 KiB) Viewed 831 times

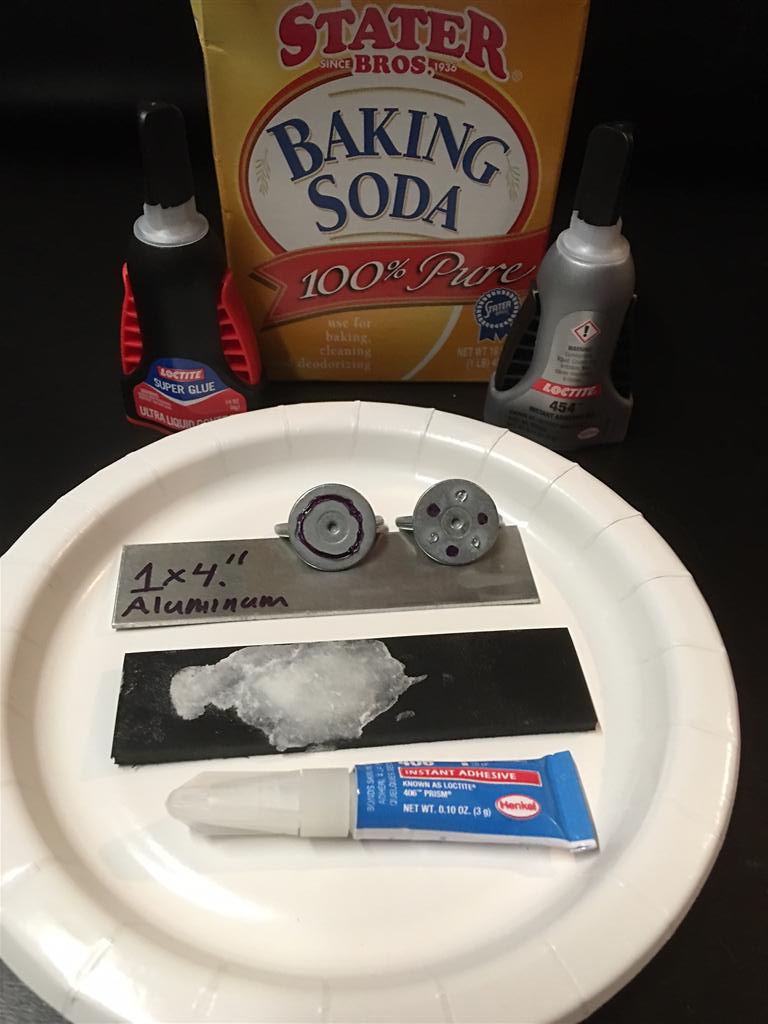

Photos # 6 & 7

Cyanoacrylates or Super Glues

1. Almost instant cure on most materials

2. Use latent moisture on parts to neutralize the acid stabilizer in the glue

3. Require a thin bond line to cure effectively.

4. Do not over-apply a Super Glue

5 Fairly rigid bond line although their are rubber toughened and flexible versions

6. Does not bond well to glass

7. Cheaper version don't handle acidic surfaces well(wood, leather, paper and some plated metals). Newer versions overcome the extra acidity in the substrates.

8. You can add baking soda or metal powder to rebuild a worn part, seal a leaky radiator hose. Luthiers( guitar builders mix it with powdered wood or bone to repair stringed instruments.

- Image6 (Large).JPG (70.33 KiB) Viewed 832 times

- Image7 (Large).JPG (94.54 KiB) Viewed 832 times