There are a few tools that will help tremendously with the firearm cleaning process. Here's a few tools that I use and that have served me well.

My Dad was a mechanic and could fix pretty much anything mechanical, and he always seemed to have just the right tool for the job, and when he didn't have the right tool, he'd make a tool to do the job. I learned from Dad that good tools are important, and I use that philosophy when I buy tools today for cleaning firearms, working on vehicles, or jobs around the house. My working motto is

"Cry Once, Buy Once" when acquiring tools, meaning a few bucks more up front to get a good tool is usually money well spent.

Screwdrivers

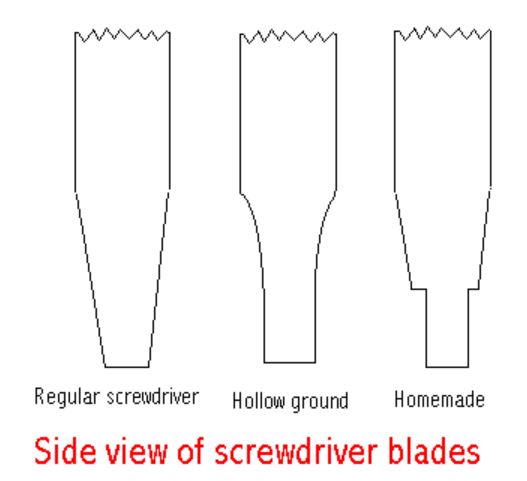

Stripping and cleaning firearms usually requires the removal of screws of all sorts, and using the wrong type of

screwdriver can lead to stripped screwhead slots or slips that mar the finish on a fine firearm.

Every gunsmith knows no two screw slots are ever the same. Because so many factories use outside vendors for screws, slot sizes can vary, even within the same model of gun. If you want to be professional about your work, you custom grind each bit to the correct size OR you get yourself a great set of gunsmithing screwdrivers.

- Screwdriver Grind Side View.JPG (29.2 KiB) Viewed 770 times

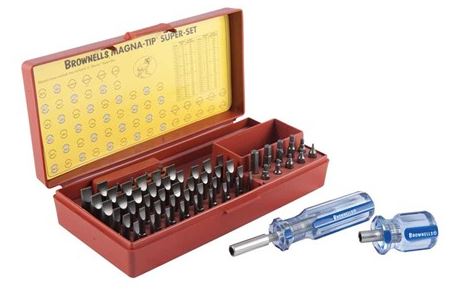

Brownells carry’s a vanity branded set of Magna-Tip screwdrivers that covers just about every screw you’re likely to encounter when working on firearms. The Brownells sets come in varying numbers of tips and handles. The best buy on Brownells Magna-Tip screwdrivers is to go with the biggest set.

The Super Set below is the 58-bit configuration, so you’ll always have a screwdriver blade that precisely fits the size and width of virtually any screw slot. You get flat blades in 9 different widths from .120" to .360", each with four to six blade thicknesses from .030" through .070" in .005"or .010" increments. Each 1½" long bit is marked with its blade width and relative thickness number, 3 for thinnest, 4 for next thicker, etc. Super Sets come with a handle of your choice. I went with two handles, a standard length and a stubby.

Brownells tools are guaranteed for life. I've found Magna-Tip screwdrivers at other places, but never assembled in a package specific to firearms and as complete as the Brownells set.

https://www.brownells.com/

- Brownells Magna-Tip SD Set.JPG (27.25 KiB) Viewed 823 times

Punches

Using the wrong punch to push out a pin can easily mar the pin or swell the pin to the point that it needs to be replaced. Similar to twisting screws with a proper screwdriver, a good

punch is needed to push pins in or out.

First, it is essential to identify the type of pin in your firearm and whether or not the pin is tapered. Roll Pins require a differnt tool than cylindrical or tapered pins, and of course tapered pins need to be pushed out towards the end of the pin with the maximum diameter. There are proper tools for each job.

For general punch use on firearms, I’ve had great results with this compact set of punches that fit easily into my range bag or cleaning kit. This set is available at Brownells and features hi-impact steel handles with knurled grips for easy holding and accurate control. These are built to withstand maximum impact with a minimum of distortion, and that is why I like these. With full brass punches, one needs to spend time caring for each end as the ends mushroom with use, whereas with the steel handles, generally only the brass end needs much care. Interchangeable and replaceable tips are available in: 5/16" Nylon with steel reinforcing pin to prevent bending or breakage while giving completely mar-free punching action; Brass in various diameters for a harder-than-nylon but softer-than-steel impact where slight discoloration is acceptable. Aluminum in two diameters for harder-than-nylon but softer-than-steel impact where slight discoloration is acceptable.

Supplied as: Basic Set with two 5/16" diameter tips (one Nylon, one Brass) and one Handle. 4-Way Set includes four Handles, one 5/16" Nylon Tip; plus one each, 3/16", ¼" and 5/16" diameter Brass Tips. 6-Way Set adds ¼" and 5/16" diameter, Aluminum Tips and 2 more handles to the 4-Way Set. On a dollar-for-dollar basis, the 6-Way set is usually the best buy.

https://www.brownells.com/gunsmith-tool ... od512.aspx

- Dowel Pin.JPG (22.86 KiB) Viewed 820 times

- Brownells ScrewIn Punch Set.JPG (32.19 KiB) Viewed 820 times

You don't want to use a flat head punch to push out a roll pin, so if your firearms have roll pins, make sure to use a

roll pin punch. The head of a roll pin punch as a dimple on the head that fits into the inside of the roll pin to prevent roll pin deformation while the shoullder of the punch does the pushing.

- Roll Pin.JPG (23.01 KiB) Viewed 820 times

- Roll Pin Punch Head.JPG (21.37 KiB) Viewed 820 times

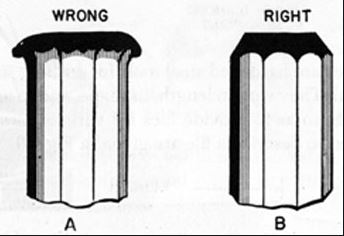

The set below is also from...you guessed it...Brownells. This is a bench type set. Beware, these are fine punches, but they do require careful use and maintenance. It is

normal for brass drifts and punches to mushroom and that mushrooming needs to be removed.

- Brownells Brass Bench Punch with Roll Pin Set.JPG (26.01 KiB) Viewed 820 times

- Mushroomed punch.JPG (14.57 KiB) Viewed 820 times

- Mushrooming punch.JPG (19.88 KiB) Viewed 820 times

Hammer

A good hammer is needed to help drive punches. I suppose the "proper" way to drive punches is with a

brass headed hammer, such as this one from Brownells. The soft brass and nylon heads are supposed to be easier on your tools.

- Brass Headed Hammer.JPG (14.72 KiB) Viewed 818 times

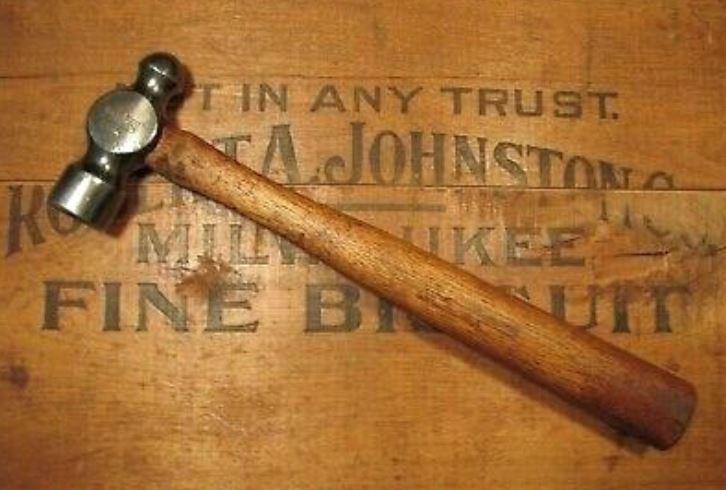

Well, I don't use a brass or nylon headed hammer. My theory is that if I'm trying to move something, I want a solid strike face and that I will control the impact via the forece of my swing.

My hammer of choice of firearm maintenance is a

Plumb Ball Peen Hammer that has been passed down from my Grandfather to my Dad and to me. The

Plumb Ball Peen Hammer is close if not over 100 years old and it still has the origianal handle, with some of the grease in that handle from work by my grandfather and father. I'm guessing this

Plumb Ball Peen Hammer is a 6oz or 8oz model and it works great for firearm maintenance. This hammer is never, ever loaned out, though my son has used it a few times and it will utlitmately end up in his tool box in a few years. The photo below is not my Plumb Ball Peen Hammer, but it should give you the idea of what I'm talking about. They just don't make hammers like this today. Intersting enough, you can find vintage hammers in excellent condition on line for often less than the cost of a current make hammer, and the vintage hammers are of superb quality.

- Vintage Plumb Ball Peen Hammer.JPG (57.46 KiB) Viewed 818 times