Trends

1. This one goes by many names. The industry has not settled on a common name.

Winch recovery Ring

Snatch ring

Soft shackle pulley

Donut pulley

The primary sales pitch is the weight savings vs. a traditional standing leg metal pulley. A typical 16,000 LB metal pulley weights about 6 LB. vs 21oz.

I have seen arguments that is safer if the line breaks since it weighs so much less. Still not something I would like to hit me.

It can only be used with synthetic winch rope and a soft shackle.

This one made by Factor 55 is representative of the concept. They call it the Rope Retention Pulley.

So far they are the only ones to add the little rubber fingers to keep the rope in the ring when slack.

It

- 20200127_120538.jpg (2.45 MiB) Viewed 833 times

From the Factor 55 web site

"The world’s first winch friction pulley with patented rope retention feature. A lightweight alternative to traditional heavy snatch blocks/pulleys. The RRP can be used to increase pulling power or redirect the winch line. The RRP is for use with SYNTHETIC ROPE ONLY and is to be used in conjunction with a soft shackle. During momentary slack, patented rope retention rubber fingers prevent synthetic winch rope from escaping the pulley groove preventing premature rope failure. The over sized hole radius provides a smooth rubbing surface and keeps the legs of the soft shackle from rubbing on the edges of the RRP. The critical friction surface has also been TEFLON treated to increase slickness and heat dissipation.

For Synthetic Rope Diameters 5/16 to 1/2 inch (8-12mm)

Billet machined 6000 series aluminum

Mil-A-8625 F Hard Anodized Surface

WLL 22,000 pounds (97.9 KN)

Weight: 21 ounces (595 g)

Made In The USA

- Typical rigging for winch ring 1-1.jpg (907.51 KiB) Viewed 831 times

We ran a test to see how much the friction affected the load on the winch. I did not test for heat issues.

We set up a double line pull between a vehicle and a tree. However, we anchored the rear of the vehicle to a stump so it could not move.

we ran the load on the winch side up to 8000 pounds. We did this for the winch ring and for a standard standing leg metal pulley.

We placed two load cell in the line by using an extension rope. One load cell measured the load the winch pulled and the other measured the load on the other leg of the double line pull.

In round numbers we saw an increase of 300 pounds on the winch side with a standard pulley and 1000 pounds with the winch ring. When the winch was stopped, the load became equal on both lines regardless of which pulley we used.

The 300 LB. and 1000 LB. readings represent the resistance the pulleys added. It also confirmed, our rule-of-thumb of adding about 10% of the load for each pulley in the rigging. The 10% rule-of-thumb was developed with steel cable and arrears to be on the high side with synthetic rope.

Keep in mind, all out testing was in the field with somewhat rough measures but adequate in my opinion for "rule-of-thumb".

_____________________________________________________________________________________________________________________________

2.

Solving an Old Issue

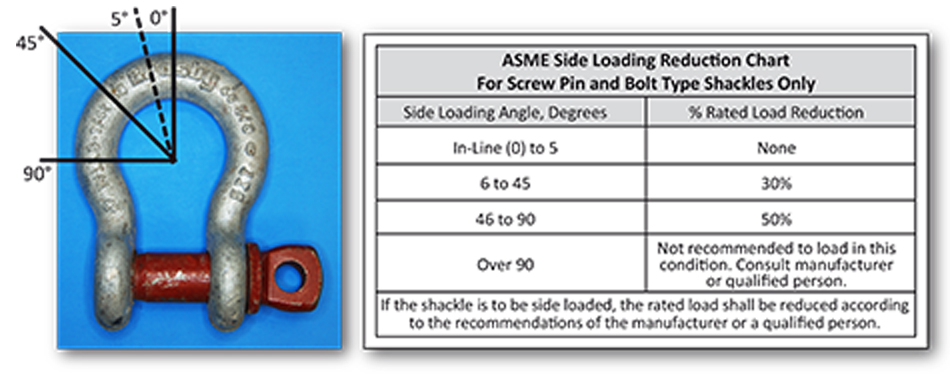

First we need to understand the strength and loading issues of the screw pin bow shackle commonly used in recovery.

The standard 3/4 inch screw pin bow shackle is rated at SLL (safe load limit) of 4.7 tons. That is about 9500 pounds. In addition the standard for minimum breaking strength is required to be at least 5 times the SLL (works out to 47,500). That is your safety margin 5 to 1. Many manufactures actually exceed this requirement in actual production. You can purchase (for a price) 3/4 inch screw pin bow shackles that are rated for higher SLL.

In practice, a standard-rated properly rigged screw pin bow shackle exceeds by a wide margin the weak link in the rigging. The weak link is almost always the line.

- shackle_side_load_chartandillustration-1.jpg (193.96 KiB) Viewed 822 times

As seen in the picture, you have the full rating of the shackle when pulling in a straight line on the bow. If you pull at a 45 degree angle you have only 70% of the strength (lose 30%). And while the illustration lists pulling on the side retains 50%, we never recommend setting up such a rigging.

A winch hook is happiest when it can center itself on the bow of a screw pin bow shackle because it self centers. Loops of a tree strap are happiest when they can ride on the bow of the shackle. If you are using a hook, you sometimes have to make the decision to place the hook on the 3/4 inch pin. The result is it will pull into the corner.

- Shackle & hook2-2.jpg (242.39 KiB) Viewed 820 times

Several companies have solved this by make winch safety stoppers that replace the hook on the end of the thimble on the winch line. The design incorporates a block that fills most of the space between the sides of the shackle.

- Shackle & Flat Link winch safety stopper-1.jpg (537.53 KiB) Viewed 820 times

This particular one is Factor 55 Flat Link with their Rock Guard in place to protect the synthetic line.

- Factor 55 Flat Link -1.jpg (244.35 KiB) Viewed 820 times

When you have a synthetic winch line the best place to store the line is completely inside on the drum to protect it from cuts. A winch stopper allows you to do this and in the case of the Factor 55 Flat link it folds flat up against the winch, it is "fat" to fill a shackle, and the hole in it is cut so the big ends of a shackle will go through if the other attachment point requires the pin.

_____________________________________________________________________________________________________________________________

3.

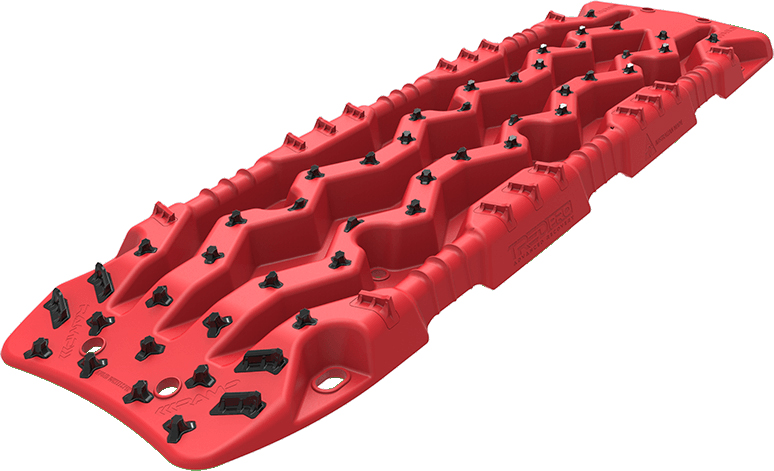

ARB TRED

- ARB Tred.jpg (219.14 KiB) Viewed 818 times

This is ARB's entry into the market. Max Trax is another perhaps more well known brand.

In my opinion, these are only useful if you are shallowly stuck as in the picture below. If you are buried to the axle, they are less effective.

To work the tire needs to grab the ramp and that can be difficult if it is not well under the tire or the angle is too steep.

ARB is addressing the issue of the tire not grabbing and wearing down the entry "teeth." I have not tested these yet.

From the ARB web site

TRED is the ultimate all-in-one off-road recovery device, specially designed to get your four-wheel drive, ATV and equipment out of trouble when traction is lost in sand, mud, sludge, or snow.

With a designated shovel feature, extreme hex grip nodules, aggressive ramp entry teeth and ultimate wear resistant properties, TRED will allow you to explore with confidence.

TRED eliminates the hazardous practices of other vehicle recovery options involving highly stressed components such as steel cables, shackles, snatch straps and winches, keeping you, your family and your vehicle safe.

List Price: List: $199.99 ; Dimension (inch) & Weight (lb):42.52”L x 12.48”W x 2.87”H 4.13”H (Nested/Stacked Pair) & 13.98lbs Packaged

- ARB Tred 2.jpg (84.09 KiB) Viewed 818 times

Features & Benefits:

• Perfect for fast, solo recoveries

• Extreme hex grip nodules along entire length of the board

• Aggressive ramp entry teeth to grab tires quickly, minimizing chance of wheel spin

• Ultimate wear resistant properties

• Unique nylon material for superior flex and durability

• Low profile for stacking and storage

• Retro fit mounts to suit most recovery board mounting options

• Ergonomic handles for shovel control

• Made by four-wheel drivers for four-wheel drivers

• The world’s first non-mechanical off-road recovery device to boast a lifetime warranty

• Various different colors available

• Also available is the shorter TRED 800, and the premium TRED Pro model