Page 1 of 5

OAUSA Net - October 15, 2020 - Automotive Adhesives I and II

Posted: Fri Oct 09, 2020 5:20 pm

by toms

Our net this week will be of particular interest to those who travel to remote locations where your usual repair service is not available. It is in these locations where the prepared traveler needs to be self-sufficient and ready to make his own repairs. But, make no mistake about it, anyone who works in his garage, works on his own vehicle, or is just handy around the house, will benefit from this net.

Kevin Paulson, KK6DGL, will be our guest this week and will be discussing various adhesives, thread lockers, repair compounds, silicones, and other products which should be in everyone's gear bag. These same products will come in handy for all your home repairs as well. Kevin's expertise in this area is impressive and the net will offer valuable information for just about everyone.

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 9:33 am

by KAP

- E64E7D25-540A-4F99-B901-EB9CF25B7024.jpeg (743.32 KiB) Viewed 1247 times

Modern vehicle makers take advantage of the the many Engineering benefits of adhesives to Manufacture and repair today’s cars, trucks and other wheeled equipment.

Auto repair shops and collision centers use many of the same products to return vehicles to a road worthy condition.

Benefits of adhesives include:

1. The bonding of multiple substrates that can’t be welded or

Bolted

2. Sealing body panels

3. Locking/sealing threaded fasteners

4. The stiffening of light weight body panels used to

Increase fuel economy.

5. Sealing engine and drivetrain components

6. Assembling and sealing electrical components &

Circuit boards

7. Prevent corrosion

8. Increased crash safety

Topics of discussion:

Safety equipment

Surface preparation

Adhesive chemistries

Vehicle applications

Additional adhesive options

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 9:34 am

by KAP

Safety equipment should always be included in any auto repair kit. Eye and skin protection are of particular importance, especially working under or in a vehicles engine compartment.

Basic equipment includes:

1. Eye or full face protection

2. Gloves- both leather and nitrile

3. Dust mask

Precautions:

1. Use adhesives in a well ventilated area.

2. Keep adhesives away from open flame or

Heat sources.

3. Avoid skin exposure. People can become

Sensitized to certain adhesive chemistries

- Basic safety equipment

- 8A936B7E-BC2F-47C5-864E-0BCEA98BB9CE.jpeg (33.4 KiB) Viewed 1273 times

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 9:57 am

by KAP

Surface prep goals and considerations:

1. Surfaces should usually be clean dry and rough

2. Try to maximize the bond area

Joint design

1. A Lap joint is better than a butt joint

2. More width is better than more overlap.

3. Verify the environmental conditions a particular adhesive will experience to mitigate failure

4. Select an adhesive chemistry that will meet the

Substrate and joint requirements. Use a flexible

To bond a flexible joint.

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 10:18 am

by KAP

Adhesive chemistries(categories):

Two Part Structurals

Solvent Based

Cyanoacrylate(C/A’s, Superglue)

Anaerobic thread lockers

Elastomers- RTV silicones and polyurethanes

Epoxy

Adhesive tapes

*Important note of Caution:

Always use those products specified by the manufacture if one is available.

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 10:44 am

by KAP

Applications

Rear view mirror bonding

Tire repair

Sealing of electrical components

Preventing fastener failure

Sealing from weather

Assembly of off road equipment( storage, camp kitchen, tools, etc)

Adhering navigation components and accessories On and around dashboard

Emergency sealing of radiators and hoses, fuel tanks and differentials

Vehicle fabric repair

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 12:28 pm

by KAP

2- Step Acrylic Structurals

These adhesives include rear view mirror and rear window defogger glues.

1. Include an adhesive and a catalyst.

2. No mixing is required.

3. Very high strength

4. Handle vibration and shock

5. Excellent magnet bonder

- Rear view mirror adhesive is a fantastic magnet bonder.

- A82E0D91-D0C3-49FB-A407-90C91C2FEB51.jpeg (28.38 KiB) Viewed 1252 times

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 12:28 pm

by KAP

Solvent Based adhesives include the following Tire plug, Weather strip, Contact cement including Headliner Sprays and Vinyl and fabric Products.

1. Usually single part

2. Required to “Air Dry”

3. The solvent could be water or petroleum based

4. Very flexible and bond a great variety of substrates

5. Medium to high strength depending on substrate

6. Can be flammable

- D329C8FF-CB7B-4A12-809C-C87135F22D54.jpeg (93.74 KiB) Viewed 1251 times

- I prefer tire repair kits that include an adhesive as it helps to lubricate and fill small irregularities when applying the plug. The adhesive is solvent based and offers almost immediate use. Great to have with you on the trail.

- D5BF51FD-F94E-4DA3-BC60-7F212EE4245B.jpeg (111.04 KiB) Viewed 1245 times

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 12:28 pm

by KAP

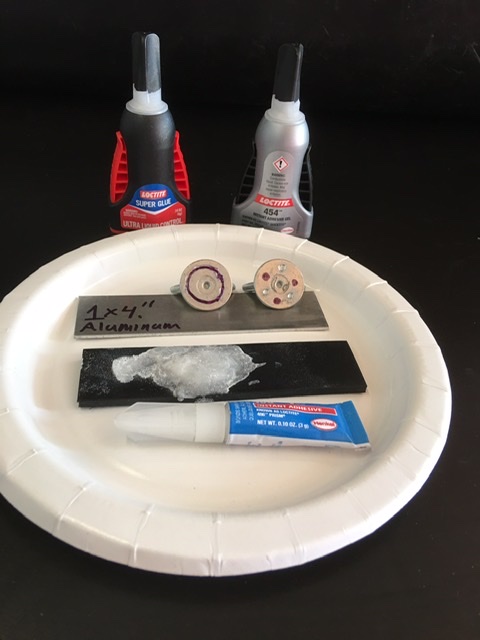

Cyanoacrylates, also known as C/A’s or simply Super Glues bond a great variety of surfaces

but do have some limitations.

1. Most have Low heat resistance

2. They tend to be brittle although some are rubber modified

3. Will bond skin instantly so gloves are advised

4. Generally poor environmental resistance.

5. Require a very thin bond line to cure properly

6. Hybrid versions offer some great advantages.

7. Baking soda, powdered aluminum or other fillers can be used to increase the

strength and to facilitate the cure in open air.

- Baking soda can be added to C/A’s to fill gaps and reinforce a repair area.

- 75F8EE76-310E-4279-AAC7-A9D9DDA38D94.jpeg (58.99 KiB) Viewed 1247 times

Re: OAUSA Net - October 15, 2020 - Automotive Adhesives

Posted: Sat Oct 10, 2020 12:30 pm

by KAP

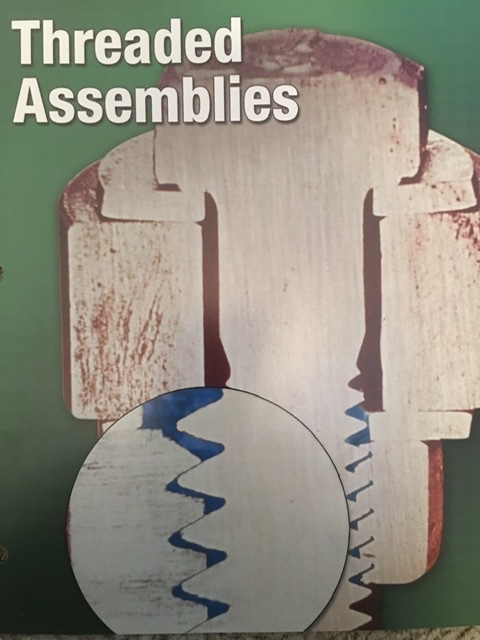

Anaerobic Thread lockers are the best way to ensure fasteners maintain clamp load and also offer

the benefit of lubricating and then sealing the threads to prevent rust and corrosion.

1. Available in low, medium and high strength and different viscosities.

2. If in doubt, use blue as it holds very well in all but the highest vibration and shock load

applications but is easily removable with the same hand tools you put the fastener on with.

3. Impervious to almost all chemicals

4. Can also be used between flat, bolted surfaces to prevent side sliding.

5. They are not glues but a liquid plastic that solidifies to fill the pours of metal surfaces to create

additional friction.

- Chemical thread lockers are designed to fully fill the air space between the threads and create friction.

- 9326DABD-B303-4814-A0B6-14AB835917C0.jpeg (76.42 KiB) Viewed 1248 times

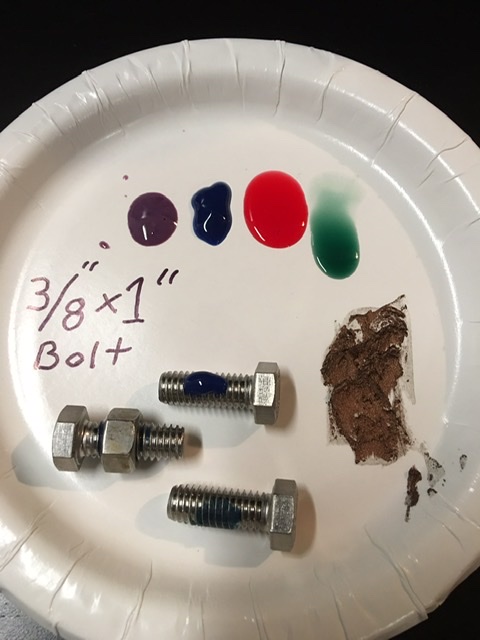

- 2-3 drops on a 3/8” fastener is sufficient to prevent failure

- DAC4CFB4-A08A-42CF-BDE5-762987A3B06D.jpeg (70.01 KiB) Viewed 1248 times

- To properly secure this wheel spacer, I used Loctite 263 red thread locker on the studs to secure it to the hub. Then I added Loctite 290, water thin thread locker between the hub and spacer. It will not come lose until heat is applied. Rust or corrosion is also eliminated

- C8F38509-69CE-454D-83EE-F97E1E1E0266.jpeg (114.61 KiB) Viewed 1248 times