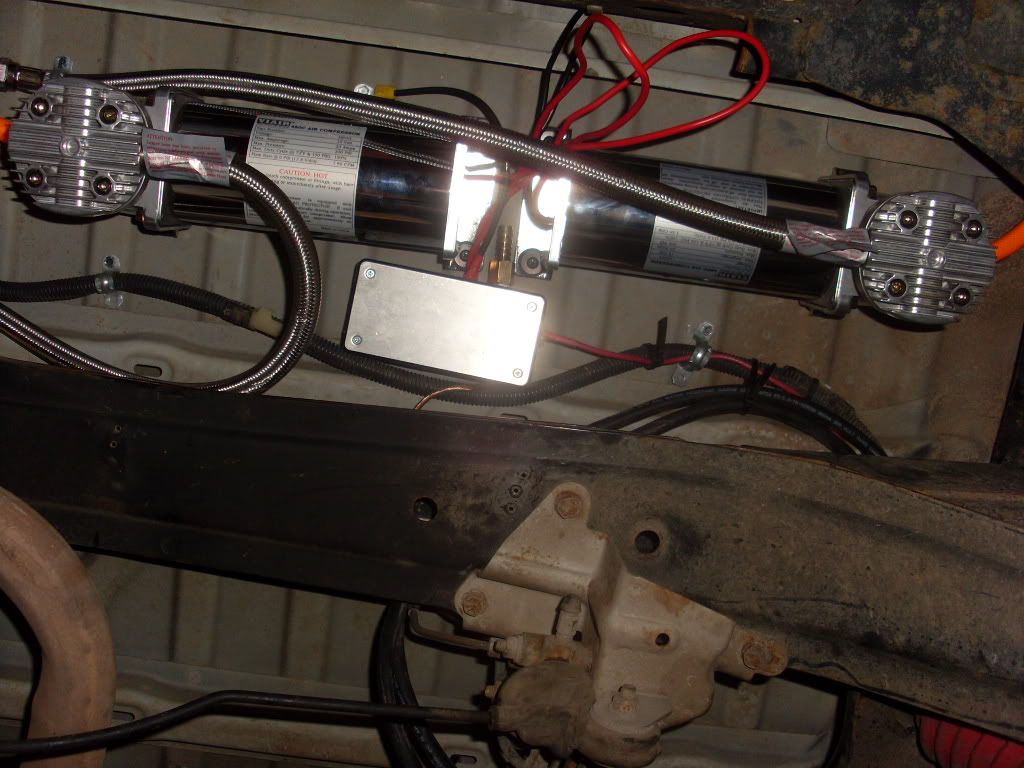

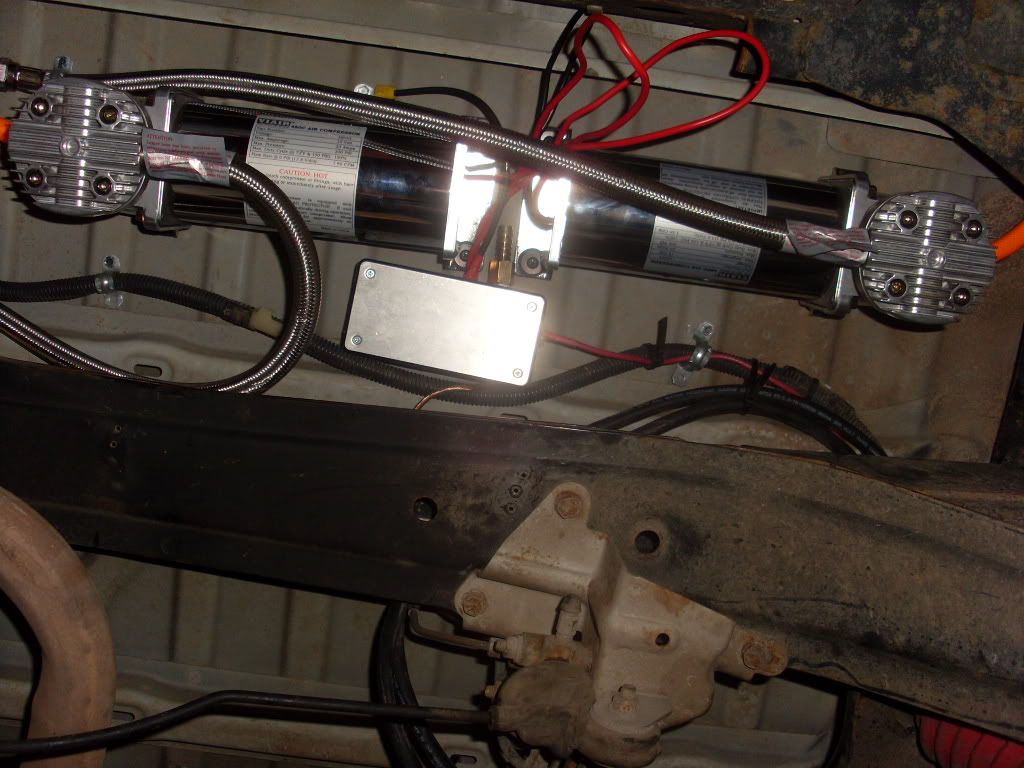

Looks cool! Where did you find that little pressure switch? Do you have a vent on the bottom of the box for the air to escape? You can take off that metal shield around the motor and you will get better cooling. That is more of a "don't burn your finger" type of thing.OU812 wrote:I’m doing the same thing with a MV50. I am only using one but I am going to use my rock rails as air tanks. They are roughly 2.5 gallons together. The MV50 will be mounted under the hood and I will run copper line to the rock rails and to hose fitting on the rear bumper. I put a 12v computer box fan in the ammo can that will run as long as the system is on. My new Softopper Jeep top is coming in the mail tomorrow so this will be put on hold for a bit but here is what it looks like so far.

OLLIE wrote:Nice set up and ideas.

There is something to consider with compressor systems. Why do you guys want air tanks? Unless you are installing an air horn set up they are pretty much useless. You need to run nearly a ten gallon tank to provide any efficiency for air tools. CO2 is smarter to use for air tools in that regard. It would save you pain and heartache to just ignore the tanks. As long as your system is tight, just coming off your compressor for the lockers will work fine. The line to the locker will hold plenty of volume for their function. Just a thought...

Users browsing this forum: No registered users and 2 guests